IMPLEMENTATION OF

GREEN HYDROGEN

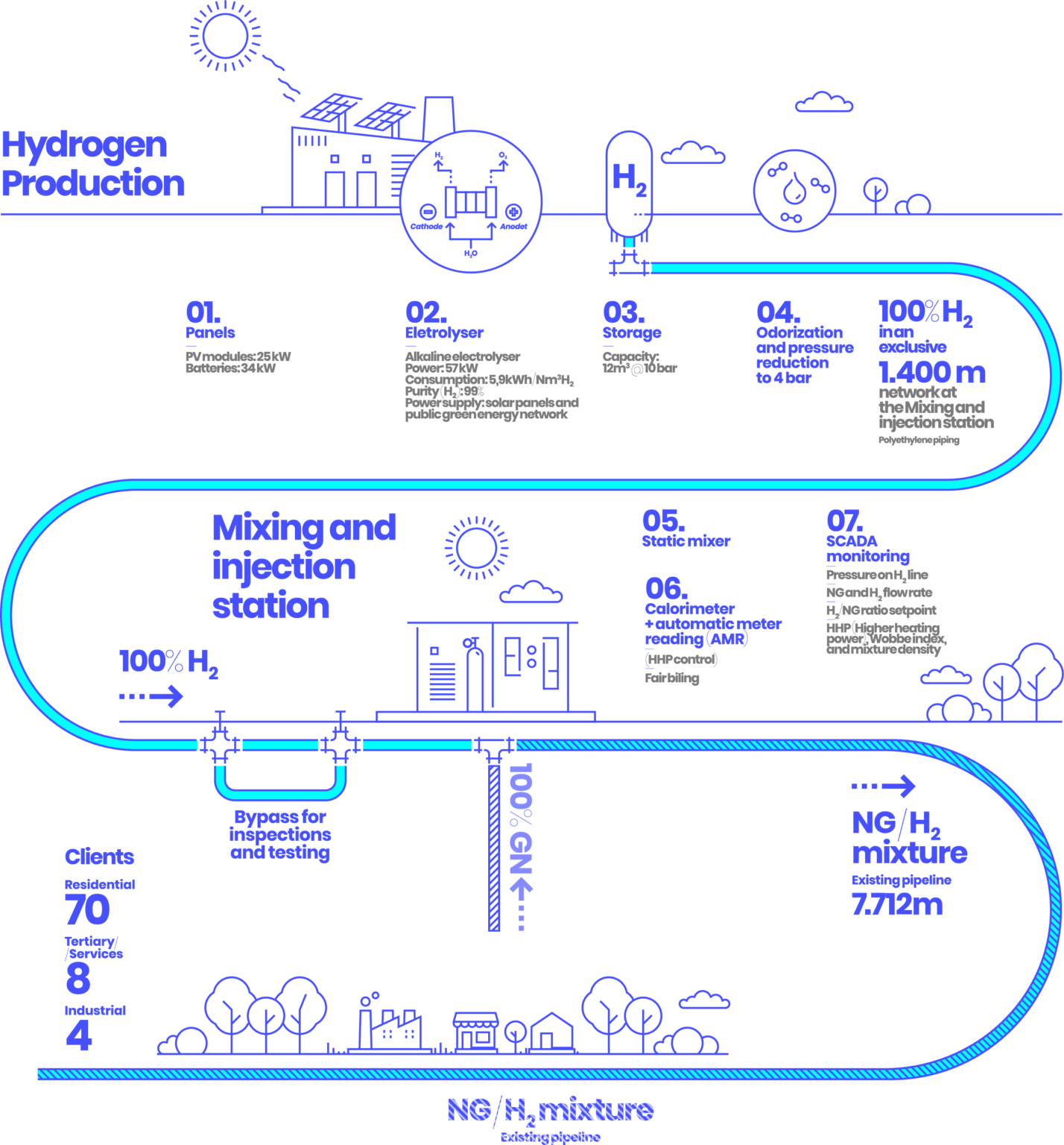

GREEN HYDROGEN PRODUCTION, MIXING AND INJECTION PROCESS

PRODUCING GREEN HYDROGEN

Aiming at the energy sustainability of our country, the project “The Natural Energy of Hydrogen” is the reflection of investment in decarbonization of the gas sector. Using a green energy alternative, this project uses a fully sustainable energy source to provide energy to homes, services and industries in Seixal, thus reducing the emission of greenhouse gases and contributing to a more sustainable energy consumption.

Hydrogen is the most abundant chemical element in nature and has been used in the past in applications such as airships and space missions. However, the pressing need to decarbonize the world economy and the possibility of producing this fuel through renewable sources make it a pillar of the energy transition. The production of green hydrogen, through the electrolysis of water, and using 100% renewable energy, makes this element an environmentally friendly energy vector, which can be used in industry, heating, mobility and power generation without any carbon dioxide emissions. In this project, the electrolyzer will be powered by solar energy, produced locally through a system of solar panels coupled with a storage unit with batteries. This green energy will then be used in the electrolysis process that will separate the hydrogen and oxygen atoms present in the water molecules (H₂O), thus producing green hydrogen (H₂).

MIXING AND INJECTION STATION

The MIS – Mixing and Injection Station – is the facility where hydrogen and natural gas are mixed and controlled before being distributed through the network.

One part of the station is where natural gas and hydrogen coexist, which, in the predefined proportions, are mixed in the “static mixer” with the aid of several valves, principally a measuring valve, and various instruments and sensors.

In the other part of the station are installed a computer (PLC), a calorimeter and other instruments, which make it possible to manage the volume of the mixture – never higher than 20% hydrogen – to control various security systems, and to establish communications with the network management system (SCADA) and with billing.

The mixture’s energy is calculated continuously by the calorimeter that informs the PLC, which sends it to the billing system.

In the event of a serious failure of the system, the MIS cuts off the hydrogen injection, always ensuring the supply with natural gas.

DISTRIBUTION NETWORK

There are two networks involved in this sustainability project. The first network, extending over approximately 1,400 metres, is dedicated to the transport of hydrogen. This section will take the energy vector from its place of production (Gestene) to the mixing and injection station. The mixing and injection station contains a blender that ensures the desired proportion of hydrogen to natural gas, which will vary between 2% and 20% by volume, a calorimeter, which will measure the calorific value of the mixture, and a control and monitoring system.

After this step, the mixture of hydrogen and natural gas is injected into the network that supplies our residential, tertiary and industrial customers. This second network consists of the on-site gas distribution infrastructure that already supplies these customers with natural gas. This network has a total length of more than 7,500 m and contains components such as valves and meters, which can be found in any area of the existing gas distribution network.

Thus, benefiting from the current gas distribution network and the local production of green hydrogen, The Natural Energy of Hydrogen will take the first steps towards the decarbonisation of the gas system in a closed network in Seixal.